Description

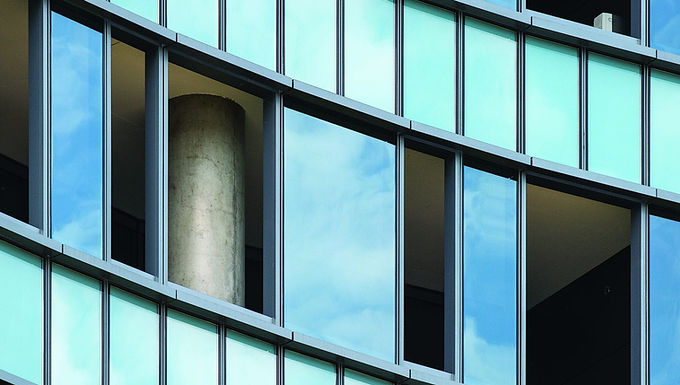

Spandrel glass is a type of glass that is commonly used in building facades to conceal structural elements or building systems, and to create a uniform appearance on the exterior of the building. The fabrication process for spandrel glass varies depending on the application and the type of opacifying product used.

Spandrel Glass Fabrication Methods

There are several categories of spandrel glass, including monolithic glass spandrels, insulating glass unit (IGU) spandrels, shadow box spandrels, and spandrels with dots and line patterns.

- Monolithic Glass Spandrels are made by applying an opacifier made from silicone-based paint or ceramic frits to the indoor surface of an uncoated glass substrate. It is recommended to use heat-strengthened glass to provide the mechanical strength needed to resist wind load and thermal stresses.

- Insulating Glass Unit (IGU) Spandrels are made of insulating glass units with an opacifier applied to the #4 surface of a dual-pane IGU or on the most interior glass surface. The exterior lite of the IGU can be coated or uncoated glass. Design professionals should consider whether using fully tempered glass for the interior lite of the spandrel IGU would be necessary to withstand the increased heat buildup if the installation design utilising spandrel IGUs incorporates insulation behind it.

- Shadow Box Spandrels are used to achieve a colour match between the vision glass and spandrel glass on a building facade. The fabrication process can involve using a monolithic lite of tinted or coated heat-treated glass or an IGU that is glazed in the spandrel area, as well as rigid, foil-backed insulation installed behind the transparent spandrel glass, with the foil facing the indoors. In many cases, the same glazing used for the vision glass is used for the spandrel glass. The back of the shadow box acts as the opaque layer to hide what’s behind it.

Advantages and Benefits

- Due to the lightweight material and innovative design, the bottomless culverts require less time, equipment, and manpower for environmentally friendly installations when compared to traditional stream and ditch crossing.

- Stackable for easy and economic transport.

- Withstands an L-150 off-highway load of 69,000 lb (31,298 kg) per axle load with tandem axle configuration overlain by 0,91 m (36 in) of backfill.